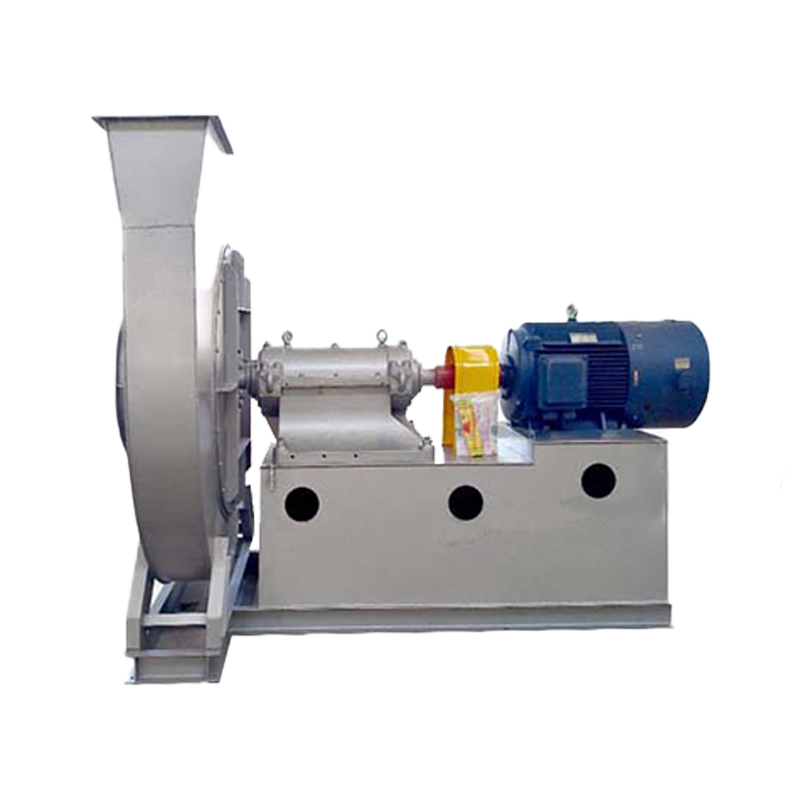

USES

8.09 high pressure centrifugal blower for cupola furnace is suitable for cupola furnace blasting performance requirements with melting rates of 1L/h, 2L/h, 3L/h, 5L/h and 7L/h. This blower can also be used for blasting of various furnaces and forging furnaces, and is also used for conveying air and non-corrosive, non-spontaneous combustion, and non-sticky gas. The temperature of the conveying medium shall not exceed 80″C, and the dust and hard fine particles contained in the medium shall not exceed 150mg/m³.

Form

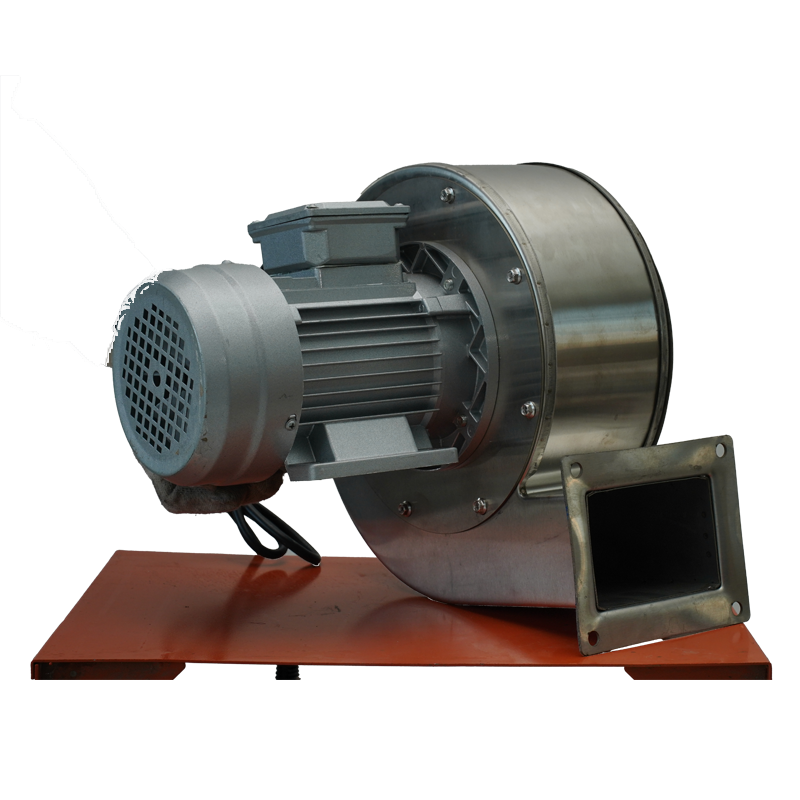

1. 8-09 and 9-12 fans are all single suction. The 8-09 fan is designed by our factory with five machine numbers: 6.8A, 7.1D, 8D, 8.5D, and 9D; the 9-12 fan is designed by our factory with six machine numbers: 6.8A, 7.1A, 7.4D, 7.7A, 8D, and 9D.

2. 8-09 fans are all in the form. When viewed from one end of the motor, if the impeller rotates in the clockwise direction, it is called a clockwise rotating fan, which is indicated by “forward”: if it rotates in the counterclockwise direction, it is called a counterclockwise rotating fan, which is indicated by “reverse”. The outlet position of the fan is indicated by the outlet angle of the casing. Both “forward” and “reverse” can be made into 0°, There are three angles: 90° and 180°.

STRUCTURAL FEATURES

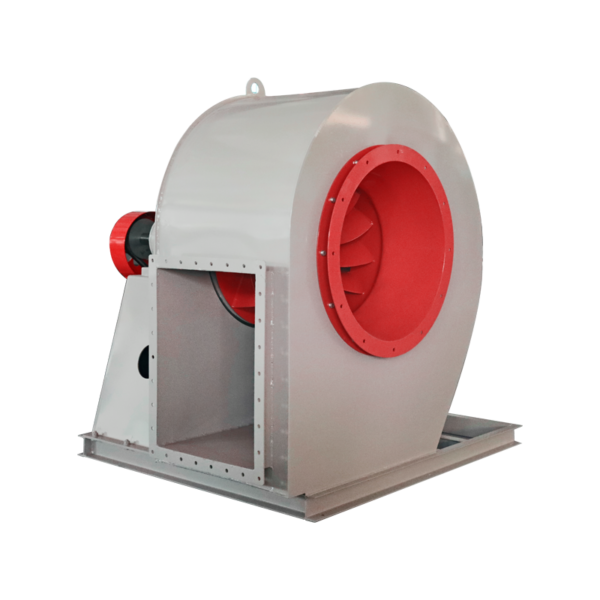

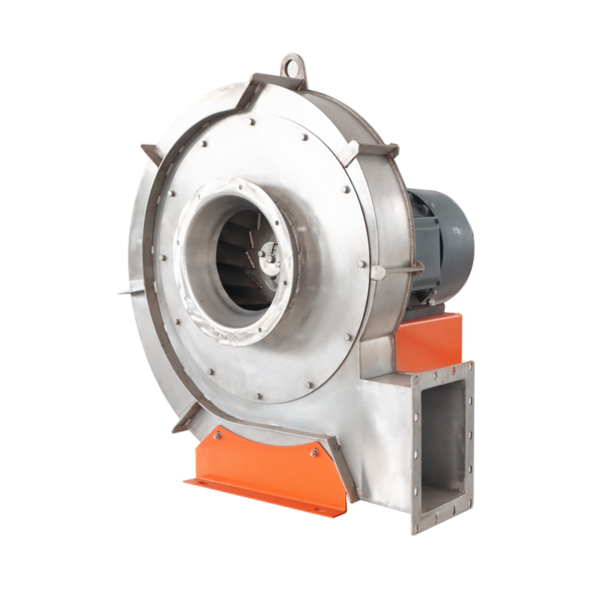

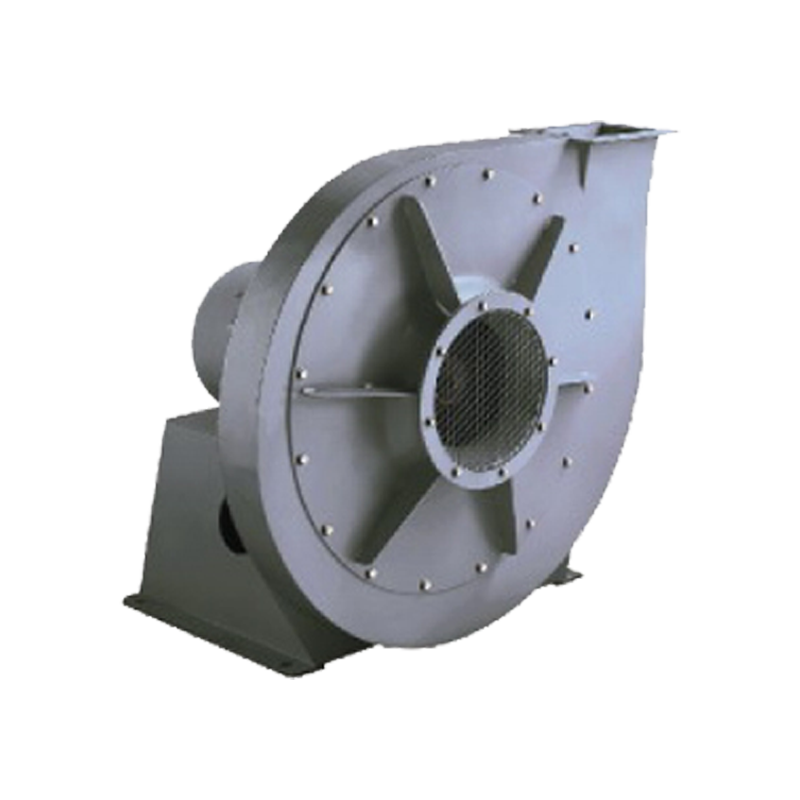

The 8-09 and 9-12 fans are composed of impellers, casings, air inlets, transmission groups, seals, and bases.

① Impeller – The blade shape is designed according to the new high-efficiency forward fan theory. After the impeller is formed, it is statically and dynamically balanced, so it runs smoothly and reliably.

② Casing – The volute casing is welded with high-quality galvanized sheets.

③ Air inlet – It is made into a convergent streamlined overall structure and fixed with bolts to the front cover plate group.

④ Transmission group – It consists of the main shaft, bearing box, coupling, etc. The main shaft is made of high-quality steel. For 8-09 Na7.1D and Na8D, rolling bearing grease is used for lubrication, and for 8-09 N8.5 and 9, rolling bearing lubricating oil is used for lubrication.

PERFORMANCE & SELECTION

1. The parameters listed in the performance table of 8-09 fans are t=20℃, atmospheric pressure Pa=101.3X10Pa, gas density ρ=1.2kg/m³.

2. Purchase precautions Before purchasing the fan, it is best for the user to measure the actual working conditions of the iron furnace (mainly pressure parameters). Then select according to the melting rate of the iron furnace and the required air volume and air pressure, so that the purchased fan meets the actual needs to avoid mismatching.

INSTALLATION

1. Before installation: All parts of the fan should be fully inspected, and any problems should be repaired immediately.

2. When installing the fan, the horizontality of the main shaft must be detected to make it meet 0.20~1000mm.

3. The sealing gap at the inlet of the fan impeller should be strictly controlled. The gap of 8-09№7.1, 8 fans is 1.0~1.5mm, and the gap of 8-09№8.5, 9 and 9-12№8, 9 fans is 1.5~2.0mm.

4. After installation, test the transmission group to check whether it is too tight or scraped with the fixed part. If any problem is found, it must be adjusted in time.

5. Test run: After the fan is fully installed and inspected, it can be tested. Before operation, the inlet or outlet gate must be closed first, so that the fan can be started under no-load conditions. After reaching the normal speed, if the situation is good, the gate can be gradually opened until the rated working condition. During the operation, the current should be strictly controlled and must not exceed the standard. After running for 20 minutes, check whether the temperature rise of the bearing box is normal, that is, the temperature rise must not exceed 40℃ above the room temperature, and the surface temperature must not exceed 70℃.

Ordering instructions: Indicate the fan’s machine number, speed, wind pressure, air volume, air outlet angle, rotation direction, motor model, power, protection level, installation method, etc.