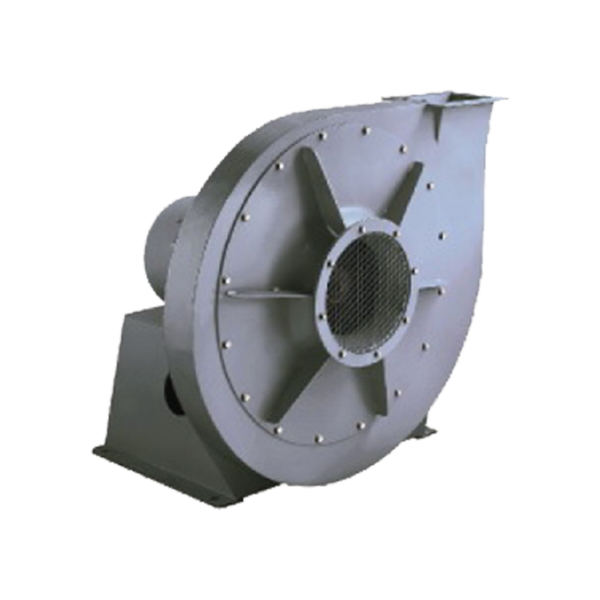

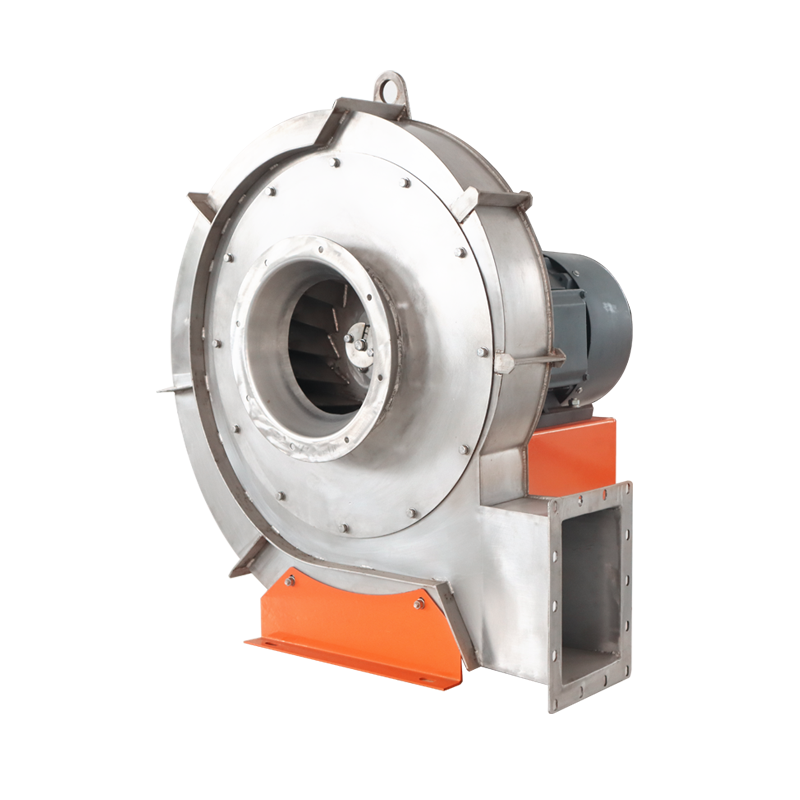

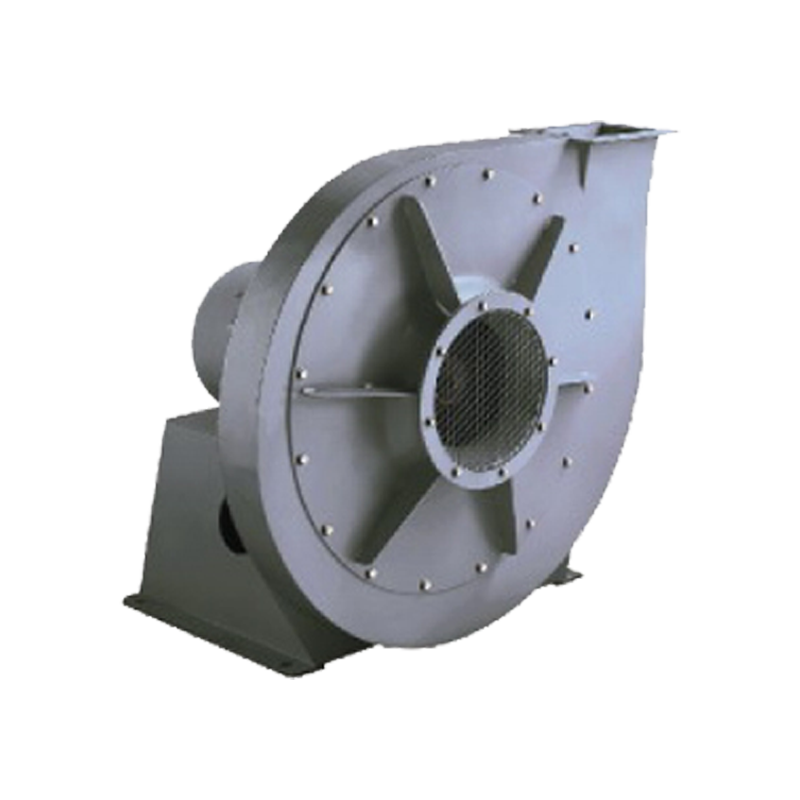

USES

9-19, 9-26 high-pressure centrifugal fans are generally used for forging furnaces and high-pressure forced ventilation. They can also be widely used to transport materials, air and non-corrosive, non-spontaneous, non-explosive, non-volatile, and non-sticky gases. The medium temperature generally does not exceed 50℃ (maximum does not exceed 80℃), and the content of dust and hard particles in the medium is not more than 150mg/m³.

TYPE

1. This fan is a single-suction type, usually with 13 machine numbers, including 4, 4.5, 5, 5.6, 6.3, 7.1, 8, 9, 10, 11.2,

12.5, 14, and 16.

2. This fan is usually made into two types: right-handed and left-handed. Looking from one end of the motor, the impeller rotating clockwise is called a right-handed fan, represented by “right”, and the impeller rotating counterclockwise is called a left-handed fan, represented by “left”.

3. The outlet position of the fan is indicated by the outlet angle of the casing. Both “left” and “right” can be made into six angles: 0º, 45º,

90º, 135º, 180º, and 225º.

4. The transmission methods of the fan are divided into three types: A type (No. 4 ~ 6.3), D type and C type (No. 7.1 ~ 16).

When the above machine number, rotation direction, air outlet angle and transmission method cannot meet your needs, we have the ability to design for you until you are satisfied.

STRUCTURAL FEATURES

No. 4 ~ 6.3 is mainly composed of impeller, casing, air inlet, bracket, etc.; No. 7.1 ~ 16 is mainly composed of impeller, casing, air inlet, transmission group, etc.

① Impeller – 9-19 type fan has 12 blades, 9-26 type fan has 16 blades, both of which are forward curved. The maximum circumferential speed of the outer edge of the impeller diffuser shall not exceed 140m/s. After the impeller is formed, it undergoes static and dynamic balance correction and overspeed operation test, so the operation is stable and reliable.

② Casing – welded into a volute-shaped whole with high-quality galvanized sheet.

③ Air inlet – made into a convergent streamlined overall structure, fixed to the front cover with bolts.

④ Transmission group – consists of main shaft, bearing box, coupling, etc. The main shaft is made of high-quality steel, the bearing box is an integral structure, using rolling bearings, and lubricated with bearing grease.

FAN OPERATION

Before starting the fan, the following preparations should be made:

① Close the air inlet valve and slightly open the air outlet valve.

② “Start the car” to check whether the fan and its system have any abnormal noise, odor, or abnormal vibration. If there is any, it should be eliminated. If not, the start-up time will be gradually extended until it runs normally.

③ When the fan starts and reaches normal speed, the bearing temperature should be checked frequently during operation to see if it is normal. When there is no special requirement for the bearing temperature, the bearing temperature rise shall not exceed 40℃ of the ambient temperature; the root mean square vibration velocity value of the bearing part shall not be greater than 6.3m/S. If the fan is found to have severe vibration, impact, rapid increase in bearing temperature, etc., it must be stopped urgently.

SCOPE OF SUPPLY

1 fan, 1 matching motor, 1 pair of anchor bolts (No. 4 ~ 6.3, 4 sets, No. 7.1 and above 8 sets) 1 set of couplings (No. 7.1 ~ 16).

ORDERING INSTRUCTIONS

1. When ordering, please indicate the fan number, speed, wind pressure, air volume, air outlet angle, rotation direction, motor model and specifications.

2. The impellers of 9-26№8 (2900r/min) and №16 (1450r/min) centrifugal fans are made of high-quality alloy steel plates. Please consult with the manufacturer when placing orders.