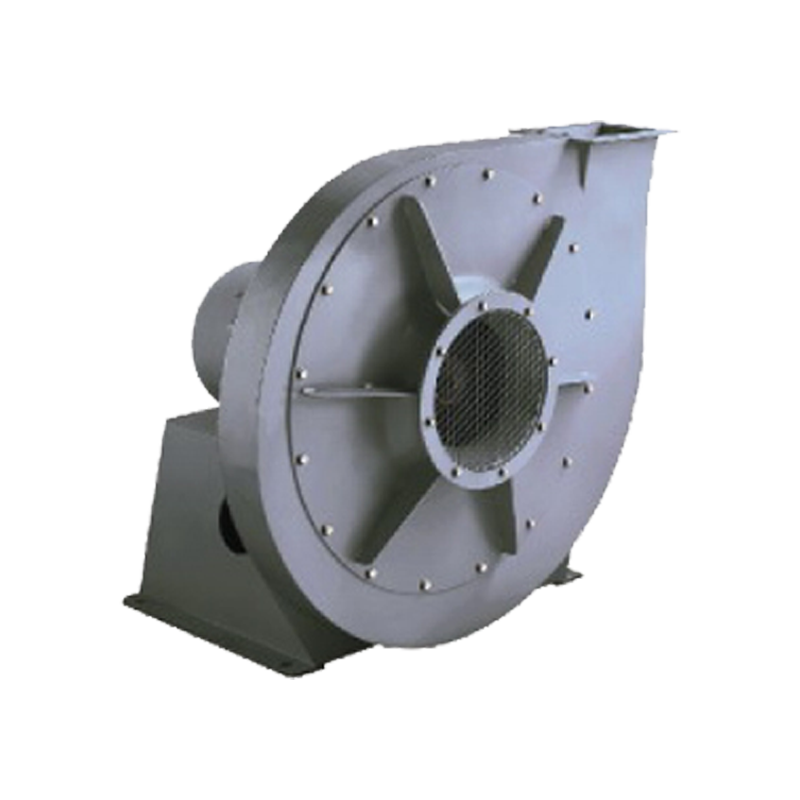

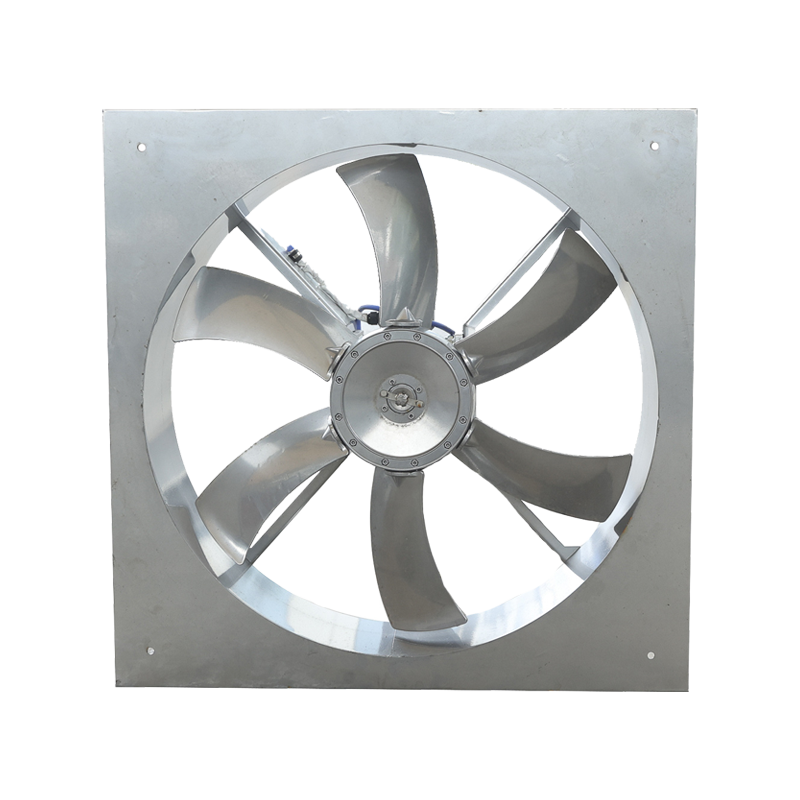

1. Product Overview

Cooling fans are heat dissipation devices used in various industrial equipment and power equipment. They cool the equipment through forced airflow to ensure stable operation in high temperature environments. They are widely used in wind power generation, power electronics, industrial machinery and other fields.

2. Main functions

– Heat dissipation: effectively reduce the temperature of the equipment through forced airflow.

– Extend equipment life: prevent equipment from overheating and extend service life.

– Improve efficiency: keep the equipment running within the optimal temperature range to improve overall efficiency.

3. Product features

– Efficient heat dissipation: use high-efficiency fans and optimize air duct design to improve heat dissipation effect.

– Low noise: low noise design reduces noise pollution during operation.

– Energy saving and environmental protection: use high-efficiency motors and intelligent control systems to reduce energy consumption.

– Durability: use high-quality materials to adapt to various harsh environments.

– Easy maintenance: modular design for easy installation and maintenance.

4. Technical parameters

– Air volume: depending on the model, it is usually between 1000m³/h~50000m³/h.

– Wind pressure: Depending on the model, it is usually between 100Pa and 1000Pa.

– Power: Depending on the model, it is usually between 0.5kW and 10kW.

– Noise level: Usually less than 70dB.

– Protection level: IP54 or higher.

– Operating temperature: -40°C to +50°C.

5. Application scenarios

– Wind turbines: used for cooling key components such as generators and inverters.

– Power electronic equipment: used for cooling equipment such as transformers and rectifiers.

– Industrial machinery: used for cooling various industrial machinery and equipment.

6. Installation and maintenance

– Installation: Provide detailed installation guidance and support on-site installation services.

– Maintenance: Regularly check the operation of fans and motors, and clean and replace worn parts in a timely manner.

7. Advantages

– Efficient heat dissipation: Ensure stable operation of equipment in high temperature environments.

– Low noise: Reduce noise pollution during operation.

– Energy saving and environmental protection: Reduce energy consumption and meet environmental protection requirements.

– Durability: adapt to various harsh environments and extend service life.

– Easy maintenance: reduce maintenance costs and time.

8. Customer Cases

– Case 1: After a certain wind farm used it, the temperature of the generator dropped by 10℃ and the failure rate dropped by 25%.

– Case 2: After a certain power electronic equipment manufacturer used it, the equipment operation stability was significantly improved and the maintenance cost was reduced by 20%.

9. After-sales Service

– Warranty period: usually 1-2 years warranty is provided.

– Technical support: 24/7 online support, fast response.

– Spare parts supply: ensure long-term spare parts supply and reduce downtime.

### Abstract

Cooling fans are key heat dissipation devices for various industrial equipment and power equipment. They have the characteristics of efficient heat dissipation, low noise, energy saving and environmental protection, durability, and easy maintenance. They are suitable for a variety of application scenarios, ensuring stable operation of equipment and reducing maintenance costs.