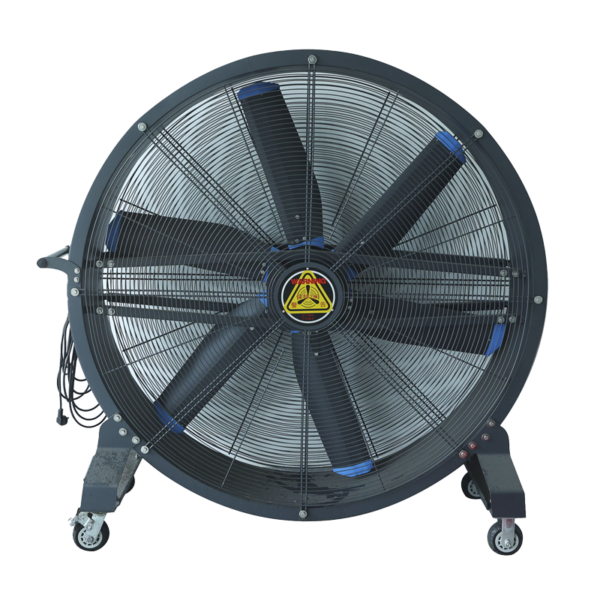

Use scenarios

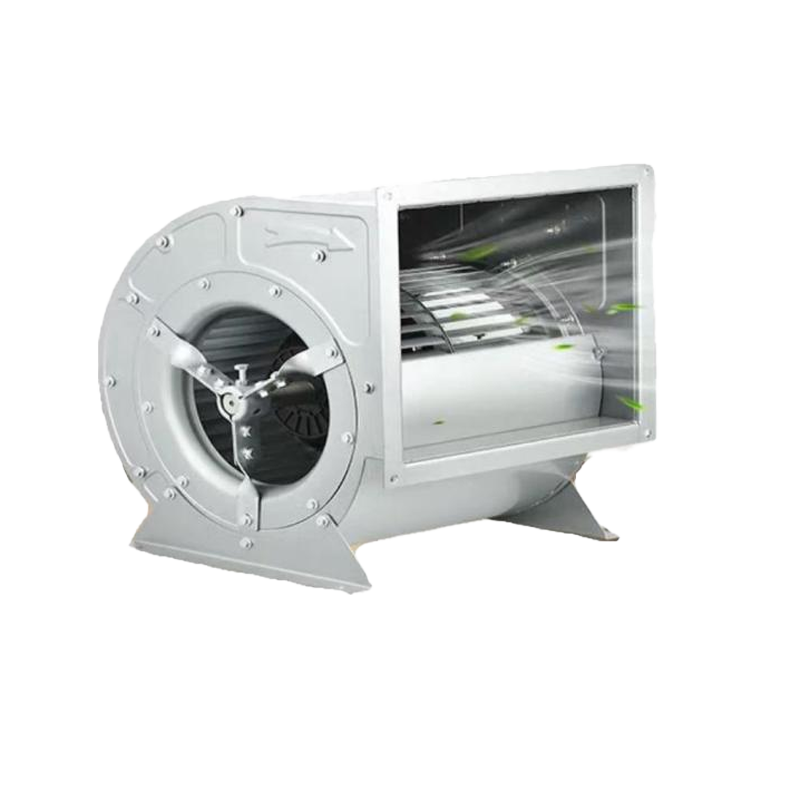

Catering kitchens: such as restaurants, hotels, canteens, etc., used to efficiently handle cooking fumes.

Food processing plants: such as fried food production lines, baking workshops, etc., used for fume discharge and purification.

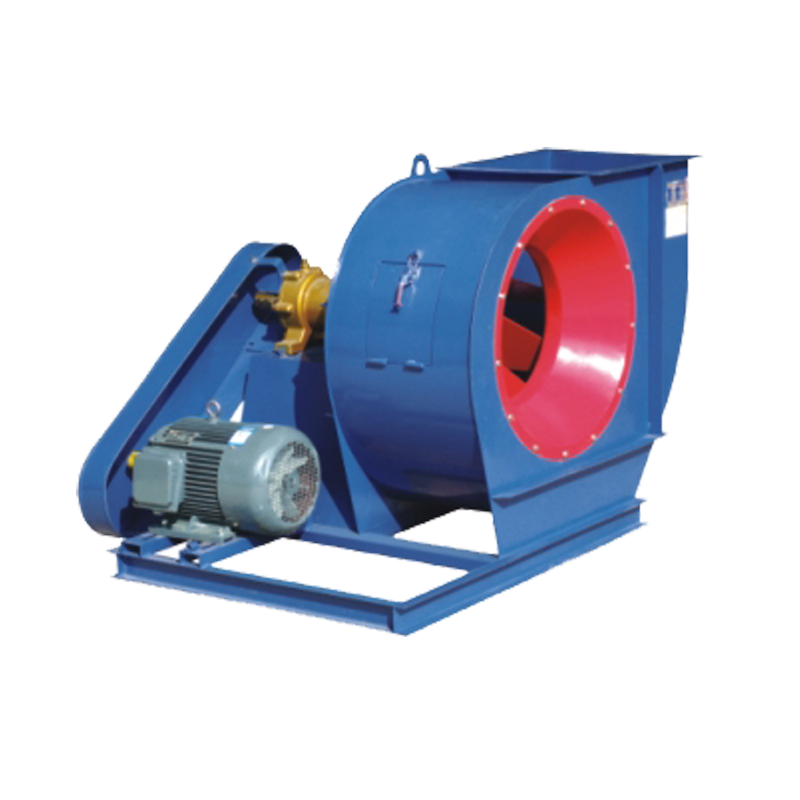

Industrial workshops: such as metal processing, chemical plants, etc., to handle oil mist and exhaust gas generated during the production process.

Commercial kitchen equipment: such as large range hoods, barbecue equipment, etc., provide efficient fume purification solutions.

Core advantages

Efficient purification: using multi-layer filtration and electrostatic purification technology, the fume removal efficiency is as high as 95% or more.

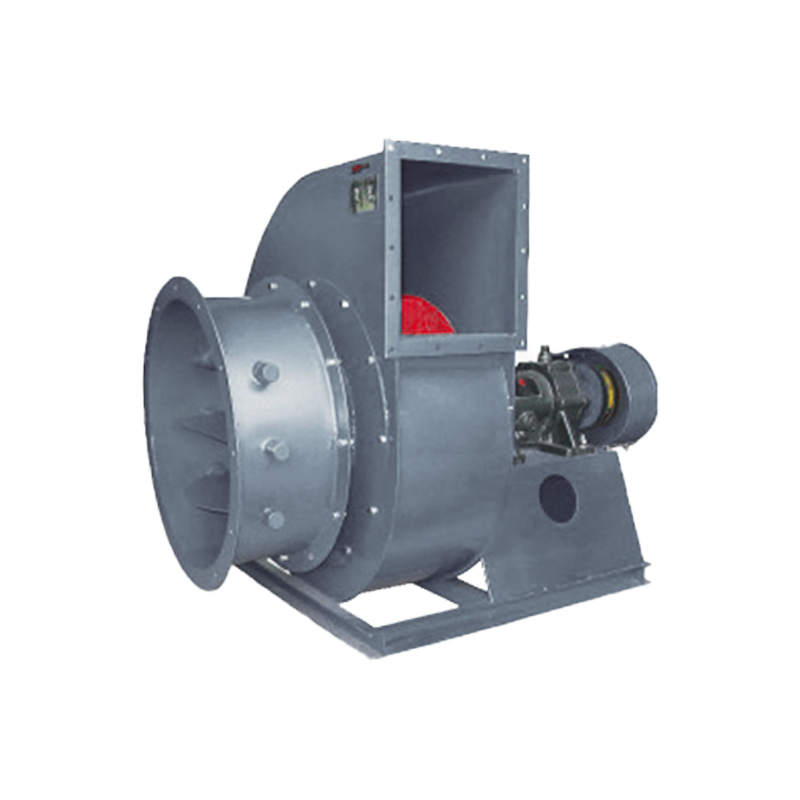

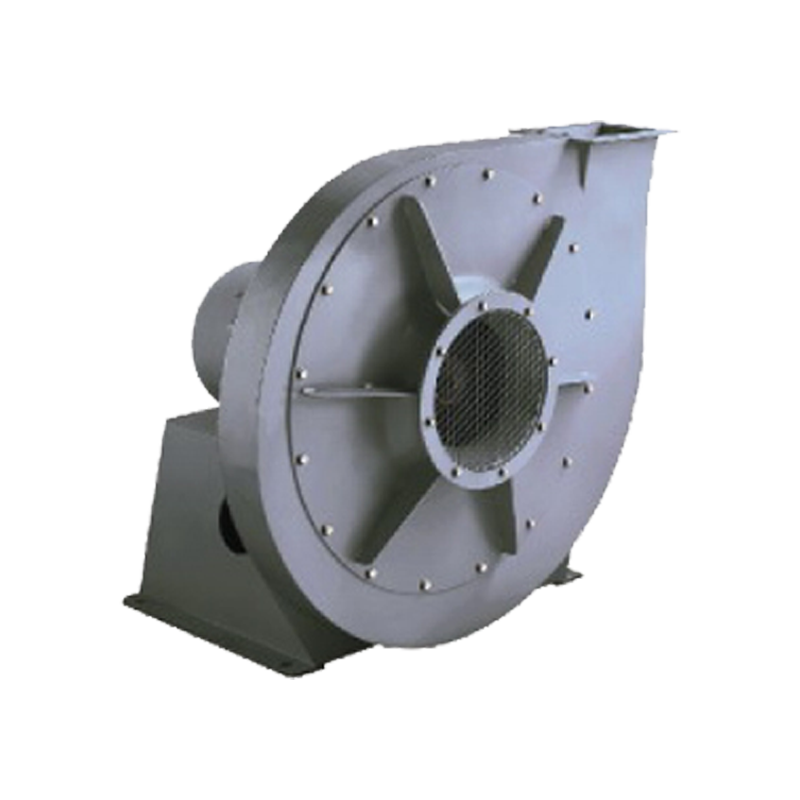

Large air volume design: ensure that the fume in the kitchen or workshop is quickly discharged to keep the air fresh.

Energy saving and environmental protection: low power consumption design, in line with national environmental protection standards, reduce energy consumption.

Low noise operation: optimize the fan structure and air duct design, low operating noise, improve the user experience.

Intelligent control: equipped with automatic cleaning function and remote monitoring system, easy operation and simple maintenance.

Strong durability: the shell and filter are made of high-quality stainless steel or corrosion-resistant materials with a long service life.

Air volume range: 1000 m³/h~30000 m³/h

Temperature range: -20℃ to 80℃