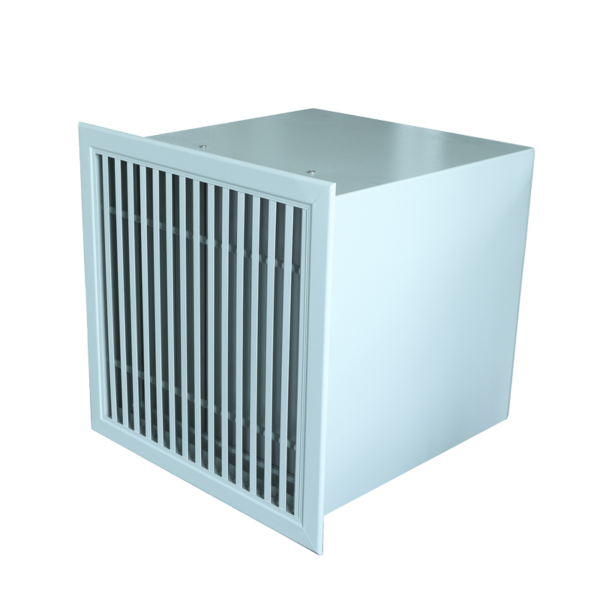

1. Use scenarios

Industrial field: Chemical plant: used for cooling and ventilation of high-temperature gas or liquid.

Steel plant: used for high-temperature slag cooling and workshop ventilation.

Power plant: used for equipment heat dissipation and waste heat emission.

Paper mill: used for ventilation and drying in high humidity environment.

Agricultural field: Greenhouse: used for air circulation and temperature regulation in high temperature and high humidity environment.

Farm: used for ventilation and humidity control of livestock and poultry houses.

Commercial field: Food processing plant: used for ventilation and cooling in high-temperature cooking or drying environment.

Hotel kitchen: used for kitchen exhaust and equipment heat dissipation in high temperature and high humidity environment.

Special environment: Tropical area: used for building ventilation and air conditioning system in high temperature and high humidity climate.

Underwater or near water environment: such as sewage treatment plant, ship, etc.

2. Core advantages

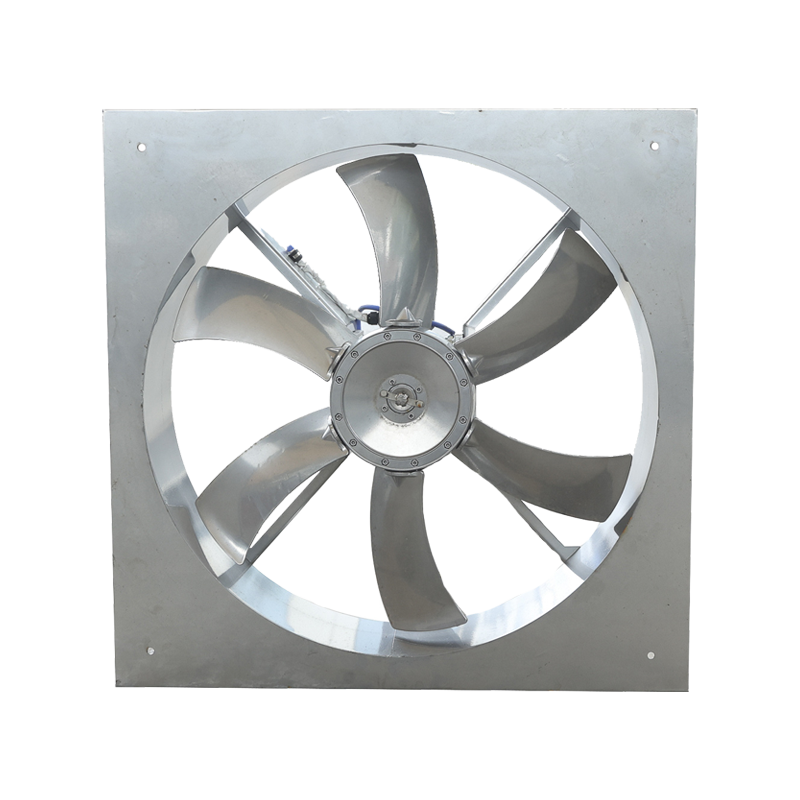

High temperature resistance: using high temperature resistant materials and design, it can operate stably at temperatures up to 120℃ or even higher.

Moisture resistance: with excellent waterproof and moisture-proof performance, suitable for environments with high humidity or direct contact with water.

Corrosion resistance: The shell and core components are made of stainless steel, fiberglass or special coating, which has strong corrosion resistance.

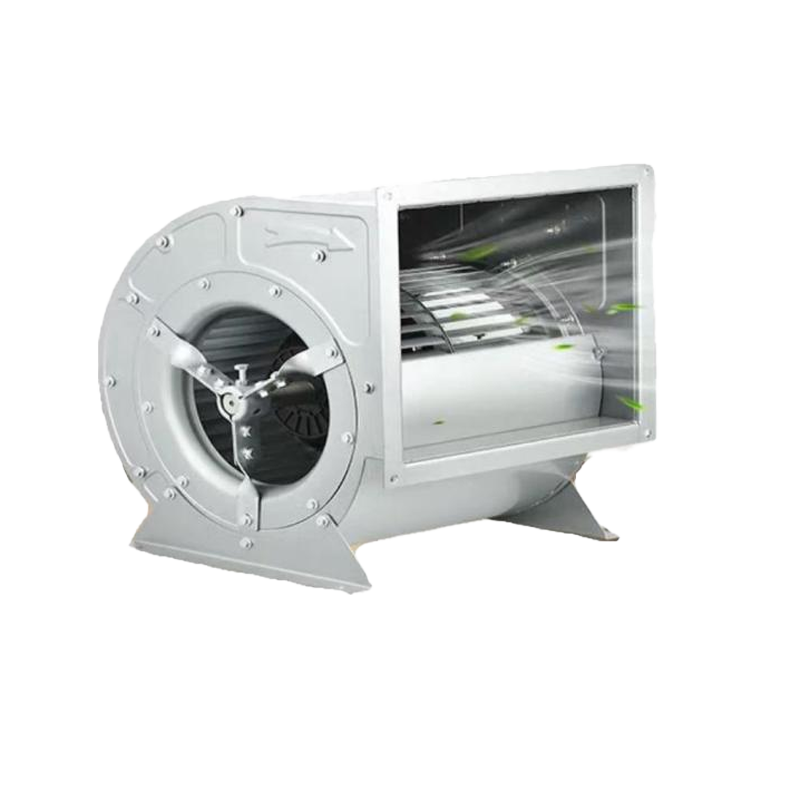

Efficient heat dissipation: Optimize the fan blade design and airflow channel to ensure efficient heat dissipation in high temperature environment.

Low noise operation: Adopt advanced noise reduction technology to reduce operating noise and improve the comfort of use.

Energy saving and environmental protection: Adopt high-efficiency motor and frequency conversion technology to reduce energy consumption and meet green environmental protection requirements.

Intelligent control: Support frequency conversion speed regulation, remote monitoring and automatic start and stop functions to improve operating efficiency and convenience.

Long life design: Adopt high-quality components and protective design to extend the service life of the equipment and reduce maintenance costs.

3. Air volume range: 500 m³/h~50000 m³/h

4. Temperature range: -20℃ to 120℃