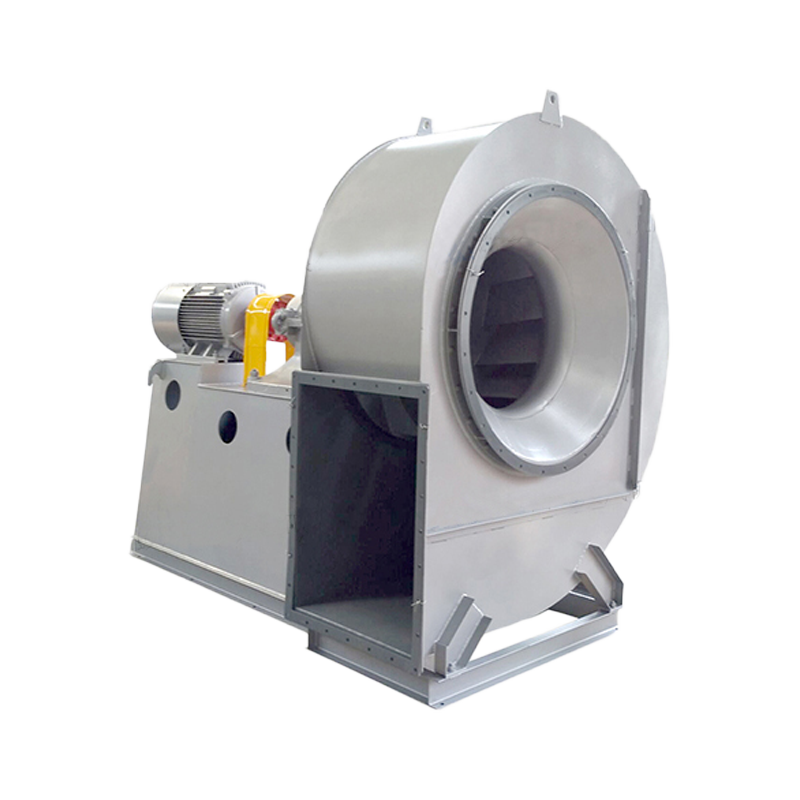

Appearance and structure

Horizontal layout, convenient for installation on the ground and other spaces in industrial sites. It is mainly composed of impeller, casing, motor, etc. The impeller is responsible for driving the gas flow, the casing protects the internal structure and guides the direction of the airflow, and the motor provides the operating power for the entire equipment.

Working principle

The motor drives the impeller to rotate at high speed, so that the air moves to the outer edge of the casing under the action of centrifugal force, forming a low-pressure area in the center of the impeller, thereby inhaling industrial waste gas containing smoke and dust, and transporting it to subsequent treatment equipment or discharge.

Performance characteristics

High-efficiency smoke exhaust and dust removal: With a large air volume, it can quickly discharge a large amount of smoke and dust generated in industrial production, and at the same time has a certain wind pressure, which can overcome resistance such as pipelines.

Wear-resistant and durable: Considering that the dust particles contained in industrial waste gas are easy to wear the equipment, its key components such as impellers are made of wear-resistant materials to extend the service life.

Stable operation: The overall structure has been optimized and can adapt to long-term continuous operation in the industrial environment, reducing the probability of failure and downtime.

Applicable scenarios

Applicable to all kinds of industrial sites that produce smoke and dust, such as mechanical processing workshops, metallurgical plants, cement plants, etc., with the corresponding dust removal equipment, it can effectively purify industrial waste gas and meet environmental emission requirements.