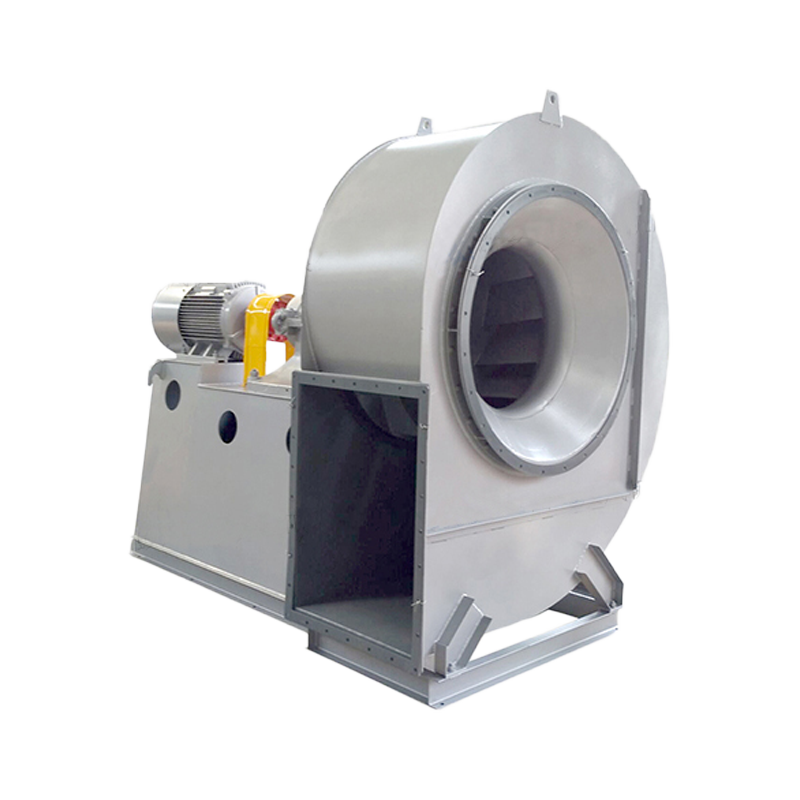

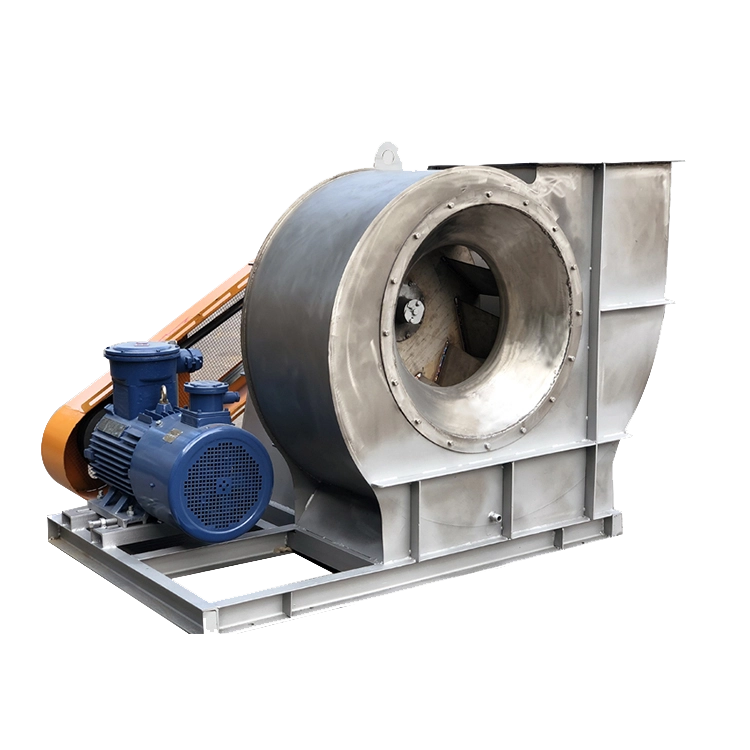

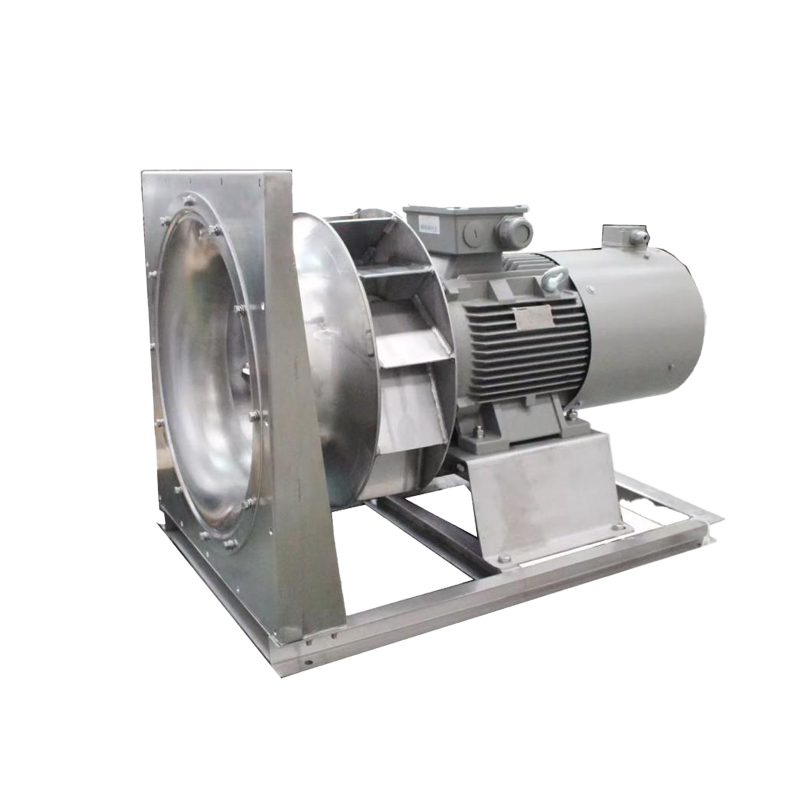

Designed for smoke exhaust and dust removal in industrial sites, it can effectively discharge smoke and dust waste gas generated in production, cooperate with purification equipment to ensure that emissions meet standards and improve the working environment.

Working principle

Centrifugal fan: Use the centrifugal force generated by the rotation of the impeller to make the gas gain kinetic energy and pressure energy. When the impeller rotates at high speed, the gas is thrown to the outer edge of the impeller, forming a low-pressure area in the center of the impeller. The external gas continuously enters the impeller under the action of atmospheric pressure, thereby realizing the transportation and discharge of the gas. In industrial smoke exhaust and dust removal, it can generate a higher pressure to extract the dust-containing smoke from the source and transport it to the dust removal equipment or discharge port.

Axial flow fan: Relying on the pushing effect of the blades on the gas when the impeller rotates, the gas flows along the axial direction. It is characterized by large air volume and relatively low pressure. It is suitable for industrial occasions that require a large amount of ventilation. In smoke exhaust and dust removal, it can quickly discharge the dust-containing gas in a large area of space, and cooperate with dust removal equipment to achieve efficient smoke exhaust and dust removal effects.

Structural composition

Impeller: usually made of high-strength wear-resistant materials, such as manganese steel, stainless steel, etc. The shape and size of the impeller will vary according to different use environments and requirements, which directly affects the performance and efficiency of the fan.

Casing: plays a protective and supporting role. It is generally welded with high-quality steel plates and has sufficient strength and sealing to prevent gas leakage.

Motor: Provides power for the fan. According to the power and use requirements of the fan, motors of different types and specifications can be selected, such as explosion-proof motors, variable frequency motors, etc.

Transmission device: Including belt drive, coupling drive and other methods, the power of the motor is transmitted to the impeller to ensure that the impeller can rotate stably and efficiently.

Air inlet and outlet: The air inlet is used to inhale dusty smoke, and the air outlet discharges the treated gas. In order to ensure the smooth and stable flow of gas, the air inlet and outlet are usually equipped with corresponding guide devices and regulating valves.

Performance parameters

Air volume: refers to the volume of gas that the fan can deliver per unit time, usually in cubic meters per hour (m³/h), and is an important indicator for measuring the fan’s smoke exhaust and dust removal capabilities.

Air pressure: the pressure difference that the fan can generate, used to overcome pipeline resistance and deliver gas to a specified location, in Pascal (Pa).

Power: includes motor power and fan shaft power, in kilowatts (kW), reflecting the energy consumed by the fan during operation.

Speed: The number of rotations of the fan impeller per minute, in revolutions per minute (r/min), and the speed directly affects the size of the air volume and pressure.

Efficiency: The ratio of the fan’s effective power to its shaft power, which reflects the degree to which the fan converts input energy into effective gas delivery capacity.

Classification

Classification by pressure

Low-pressure fan: The wind pressure is generally below 1000Pa, suitable for systems with low ventilation resistance, such as some simple workshop smoke exhaust or supporting ventilation of small dust collectors.

Medium-pressure fan: The wind pressure is between 1000-3000Pa, which can be used for smoke exhaust and dust removal systems with medium resistance, such as the smoke exhaust of some medium-sized industrial furnaces.

High-pressure fan: The wind pressure is greater than 3000Pa, mainly used for smoke exhaust and dust removal systems with high resistance and long-distance transportation, such as high-temperature flue gas dust removal in large cement plants and steel plants.

Classification by use

Boiler induced draft fan: Specially used for flue gas emission after boiler combustion, it needs to have high temperature resistance, corrosion resistance and other characteristics, and can operate stably in high temperature and high dust environment.

Industrial furnace exhaust fan: Suitable for smoke exhaust and dust removal of various industrial furnaces. According to the different types and process requirements of the furnace, it may need to have different performance characteristics, such as corrosion resistance and explosion resistance.

Dust collection fan: Mainly used in conjunction with dust collection equipment to collect dust generated during the production process. The fan is required to have good wear resistance and sealing to prevent dust leakage.

Features

High wear resistance: Since there are a lot of dust particles in the industrial smoke exhaust and dust removal environment, the impeller, casing and other parts of the fan are prone to wear. Therefore, the use of wear-resistant materials and special surface treatment processes can effectively extend the service life of the fan.

High temperature resistance: In some industrial production processes, the exhaust gas temperature is high. The fan needs to have good high temperature resistance and be able to operate normally in a high temperature environment to ensure the smoke exhaust and dust removal effect.

Good sealing: In order to prevent the leakage of dusty smoke and cause secondary pollution to the environment, the fan has good sealing. By using sealing materials and sealing structures, the stability and safety of the gas during the transportation process are ensured.

High efficiency and energy saving: Using advanced design concepts and manufacturing processes, optimizing the impeller and flow channel design, improving the efficiency of the fan, while meeting the requirements of smoke exhaust and dust removal, reducing energy consumption and saving operating costs.

Intelligent control: Some fans are equipped with intelligent control systems, which can automatically adjust the operating status of the fan according to parameters such as smoke flow, temperature, and dust concentration, realize energy-saving operation and remote monitoring, and improve the automation level and management efficiency of industrial smoke exhaust and dust removal systems.

Application scenarios

Widely used in metallurgy, chemical industry, machinery manufacturing, building materials and other industries, meeting the smoke exhaust and dust removal needs of factories of different sizes.