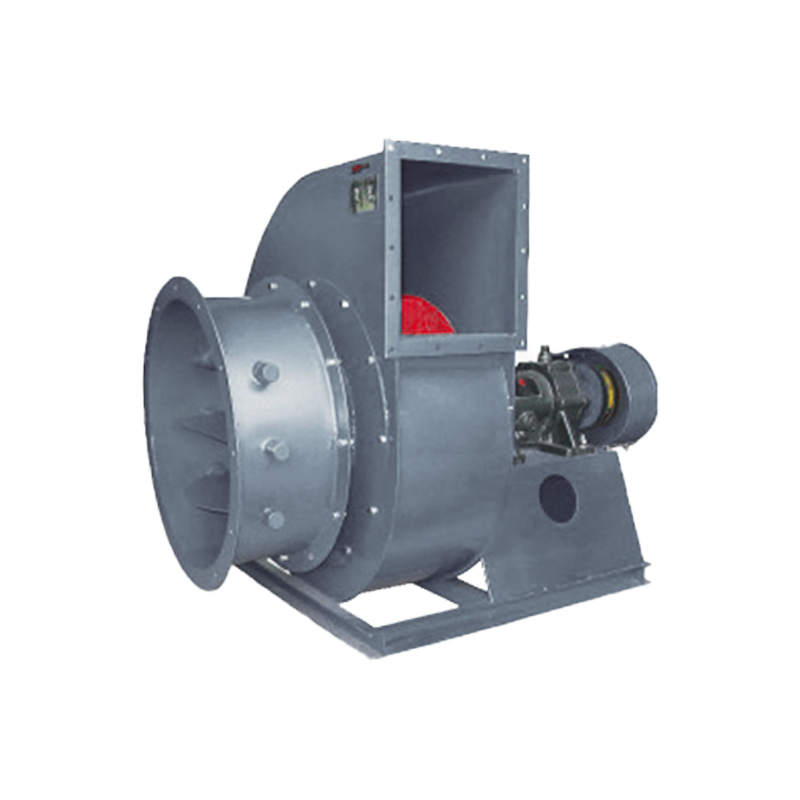

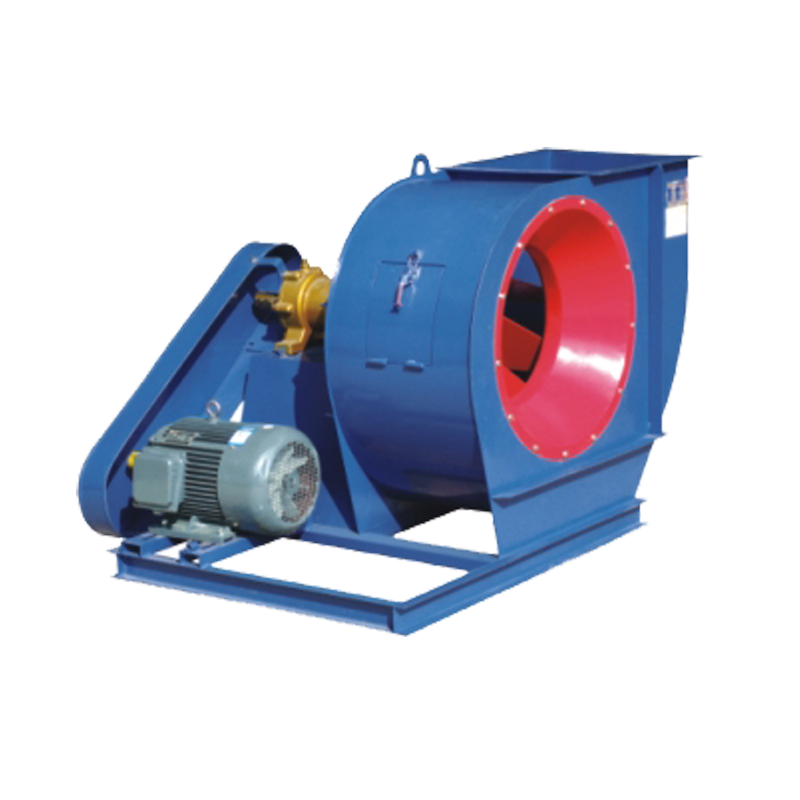

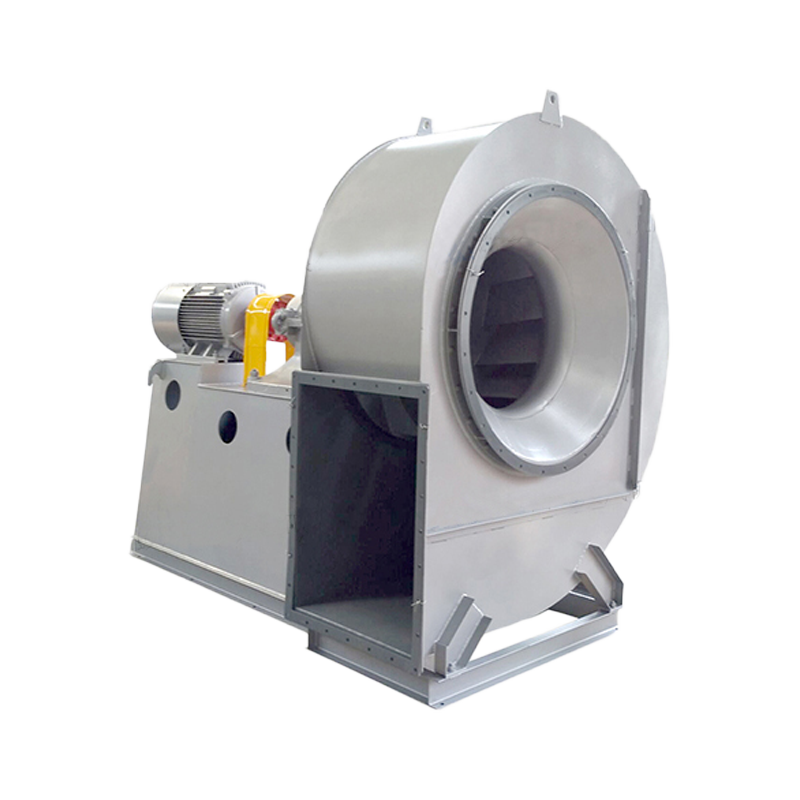

1. Product Overview

Offshore wind turbine cabin heat dissipation air-to-air cooler is a high-efficiency heat dissipation device designed for offshore wind power equipment. It is used to cool key components in the cabin, such as generators, inverters, etc., to ensure stable operation in harsh environments with high temperature, high humidity and high salt fog.

2. Main functions

– Heat dissipation: Through air-to-air heat exchange, the internal temperature of the cabin is effectively reduced.

– Anti-corrosion: Corrosion-resistant materials are used to adapt to the high salt fog environment at sea.

– Dust and waterproof: With high protection level (such as IP55, IP66), dust and moisture are prevented from entering.

– High efficiency and energy saving: Optimized design, reduced energy consumption, and improved overall efficiency.

3. Product features

– High efficiency heat exchange: Advanced fin and flow channel design is used to improve heat dissipation efficiency.

– Corrosion-resistant materials: Use stainless steel or specially coated aluminum to extend service life.

– Modular design: Easy to install and maintain, reducing downtime.

– Intelligent control: Equipped with temperature control and wind speed adjustment functions, automatically optimize heat dissipation.

4. Technical parameters

– Heat dissipation power: Depending on the model, it is usually between 10kW and 100kW.

– Protection level: IP55 or higher.

– Operating temperature: -40°C to +50°C.

– Wind speed range: 0.5m/s to 5m/s.

– Noise level: Usually below 65dB.

5. Application scenarios

– Offshore wind farms: used for cabin heat dissipation of offshore wind turbines.

– Coastal areas: suitable for heat dissipation of industrial equipment in high humidity and high salt spray environments.

6. Installation and maintenance

– Installation: Provide detailed installation guides and support on-site installation services.

– Maintenance: Modular design facilitates cleaning and maintenance, and regular inspections are recommended.

7. Advantages

– High reliability: Adapt to harsh environments and ensure long-term stable operation.

– Energy saving and environmental protection: Efficient heat dissipation and reduced energy consumption.

– Economical: Reduce maintenance costs and extend equipment life.

8. Customer Cases

-Case 1: After using it in an offshore wind farm, the cabin temperature dropped by 15°C and the failure rate decreased by 30%.

-Case 2: After using it in a coastal factory, the equipment operation stability was significantly improved and the maintenance cost was reduced by 20%.

9. After-sales Service

-Warranty period: usually 1-2 years warranty.

-Technical support: 24/7 online support, fast response.

-Spare parts supply: ensure long-term spare parts supply and reduce downtime.

### Summary

Offshore wind turbine cabin heat dissipation air-to-air cooler is a key component of offshore wind power equipment. It has the characteristics of efficient heat dissipation, corrosion resistance, dust and water resistance, etc. It is suitable for harsh environments, ensuring stable operation of equipment and reducing maintenance costs.