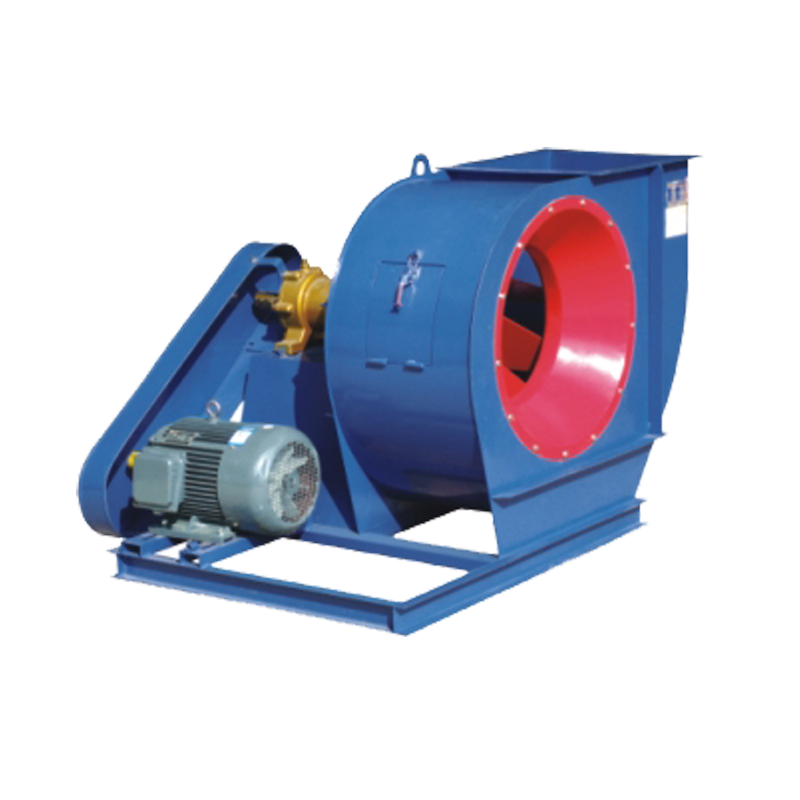

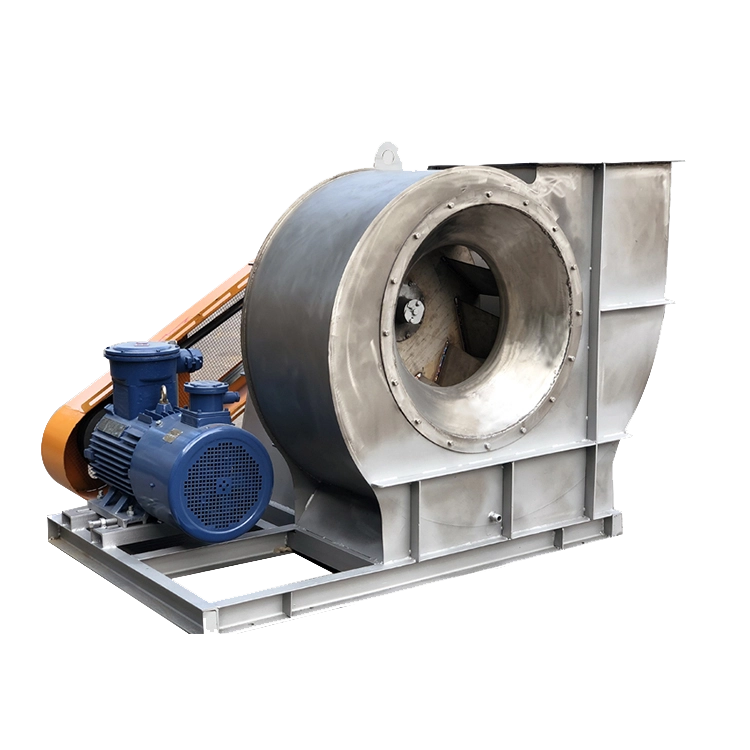

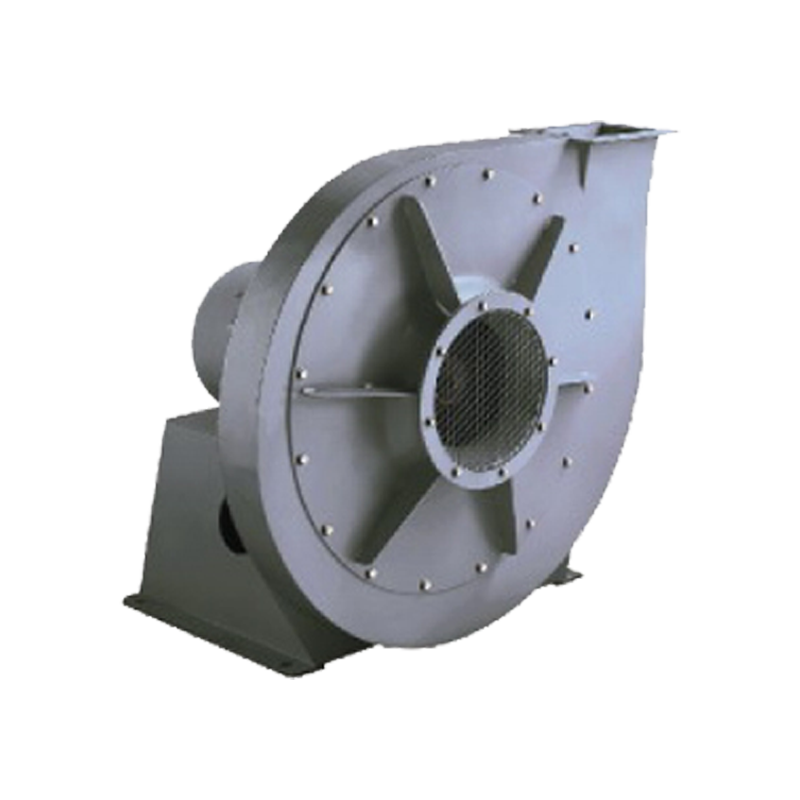

Working Principle

The turbo medium-pressure fan is generally a centrifugal fan. It relies on the input mechanical energy and uses the high-speed rotating impeller to accelerate the gas, then decelerate and change the flow direction, so that the kinetic energy is converted into potential energy (pressure). The gas enters the impeller from the axial direction, changes to the radial direction when flowing through the impeller, and then enters the diffuser. In this process, the power equipment drives the impeller to rotate, sucking air from the air inlet, and the rotation of the blades exerts a dynamic effect on the gas, increasing the pressure and speed of the gas. The gas is discharged from the exhaust port along the blade channel under the action of centrifugal force.

Performance characteristics

1. High pressure: through the special impeller design and structure, it can generate relatively high pressure, which meets some application scenarios that have certain requirements for gas pressure.

2. Large air volume: It can provide a large gas flow rate, and can quickly and effectively transport and circulate the gas.

3. Low noise: adopt an integrated sound-proofing facility, or optimize the impeller design, reduce vibration, etc. to effectively reduce the noise during operation.

4. Lightweight: Aluminum alloy is usually used, which greatly reduces the weight of the fan, making it easy to install and carry, and also reduces the requirements for the installation foundation.

5. High reliability: In addition to the impeller, there are no other moving parts, and the impeller is directly connected to the motor without gears or transmission belts, so it is highly reliable and almost maintenance-free.

6. Oil-free and pollution-free: The impeller does not contact any parts when rotating, and does not require lubrication, which can ensure that the discharged gas does not contain oil, and is suitable for occasions with high requirements for gas purity.

7. Easy installation: It is fully equipped and can be installed and used at any time, and can be installed in any horizontal or vertical direction.

8. Wide range of voltage applications: Universal voltage type, 50Hz and 60Hz are available, whether in countries using 60Hz high voltage or countries and regions using 50Hz voltage.

Product Configuration

1. Motor: Made according to European CE specifications, usually driven directly by a 2-pole motor with IP54 and F-class insulation. There are also motors with IP55 standards, F or H-class insulation, 3C and CE certification, and special shaft design, suitable for long-term use.

2. Oil seal: Use a maintenance-free shaft seal to separate the motor and the blower body to prevent foreign matter from entering and ensure the normal operation of the blower.

3. Housing: Cast separately from the motor housing, with a smooth and defect-free surface. Generally, it adopts a die-casting process and has a beautiful appearance.

4. Muffler: Both the exhaust and intake pipes are equipped with mufflers to reduce noise.

Application Field

Widely used in printed circuit board (PCB) equipment, cleaning equipment, canned beverage equipment, plastic peripheral equipment, self-adhesive trademark printing equipment, woodworking machinery, kiln mining, burners, dust collectors, incinerators, powder three-dimensional conveying, dryers, glass industry, ice making industry, mechanical cooling, general air supply and other industries. It can also be used for powder and granular conveying, textile weaving dust collection, paper cutting machine air cushion, sewage treatment, industrial mining blasting, heavy oil injection, paper pulp dehydration, shuttleless looms, glass industry and ice factory air pumps, tunnel engineering compressed air, aquaculture oxygen supply, etc.

Common models

1. CX series: such as CX-1/4 (200W), CX-75S (400W), CX-75 (750W), CX-100 (1.5KW), etc.

2. TB series: such as TB-201 (0.75KW), TB-202 (1.5KW), TB-505 (2.2KW), TB-1007 (5.5KW), etc.

3. HTB series: such as HTB75-302, HTB75-032, HTB100-102, HTB100-203, etc.

4. PF series: PF-75, PF-100L, PF-125L, PF1502, etc.