Scope of application:

Suitable for dust removal and purification in sandblasting industry, mining industry, metallurgical industry, wood processing, grain industry, coal industry, building materials industry, electric power industry, foundry industry and other industries.

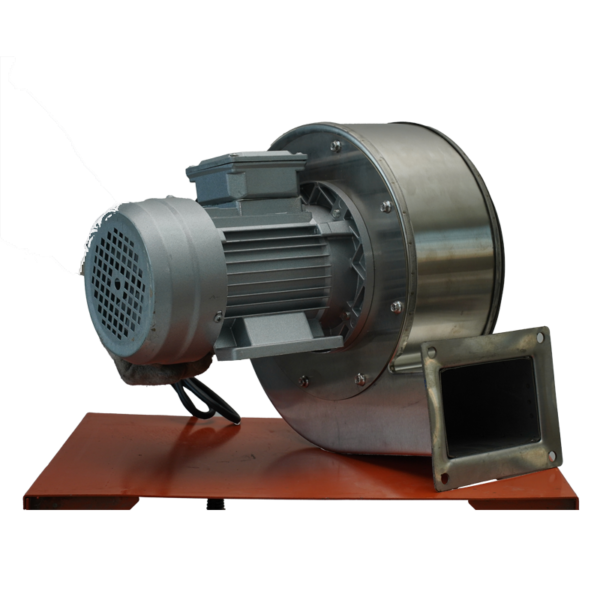

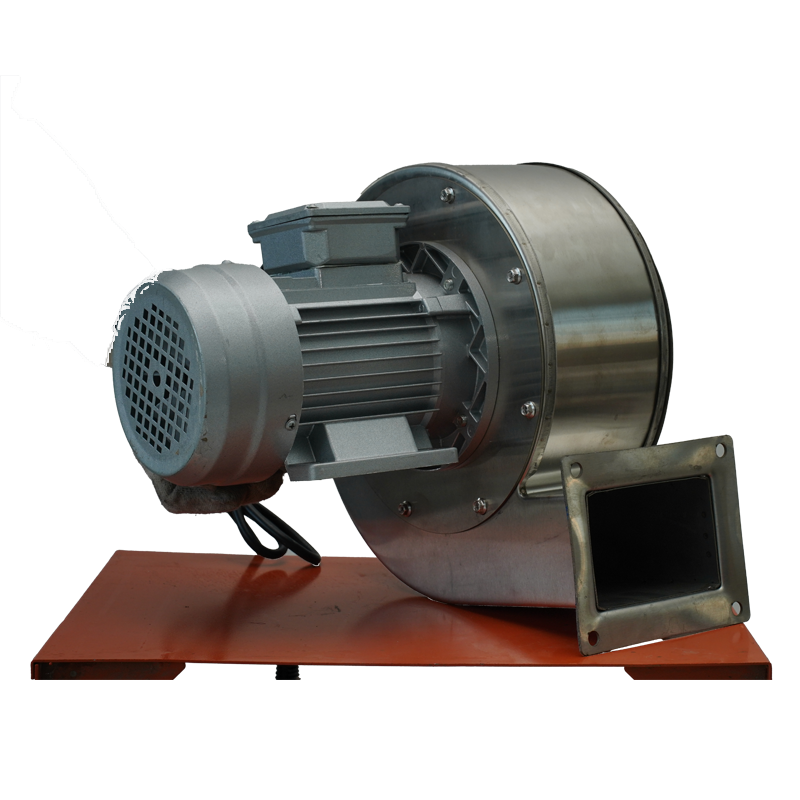

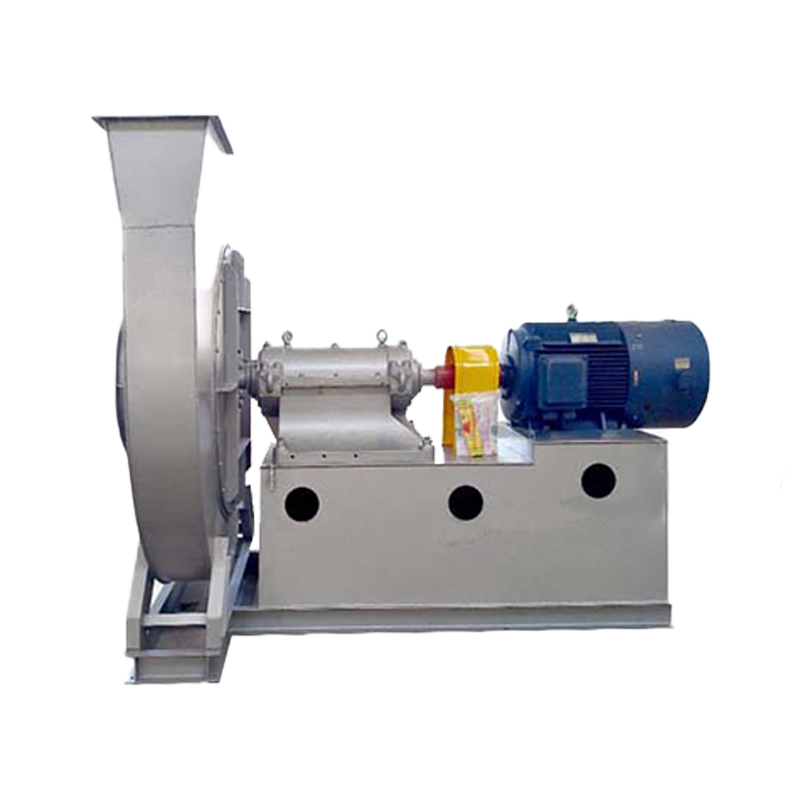

Structure

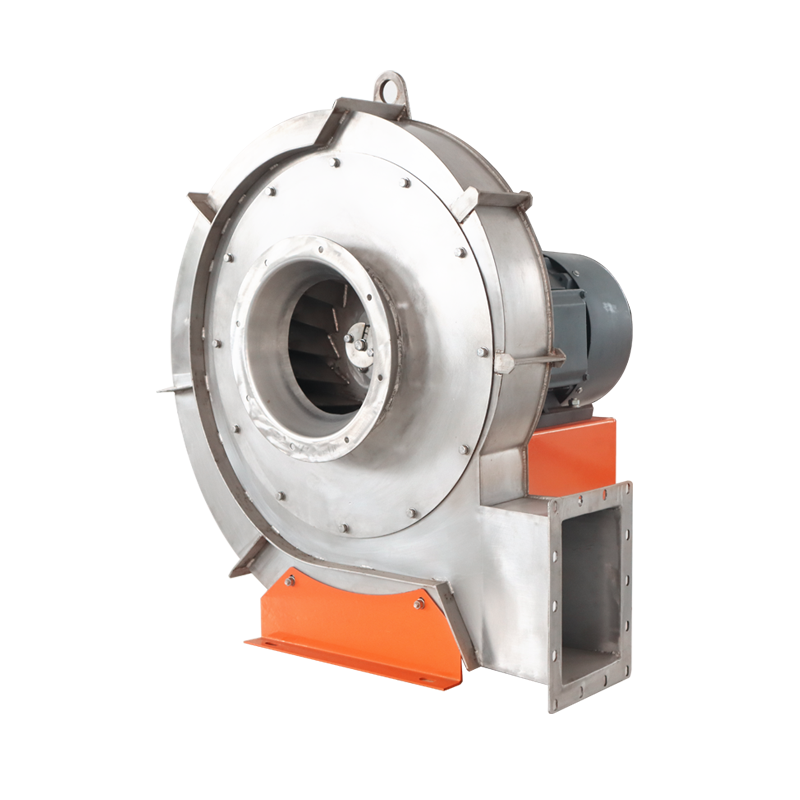

It is mainly composed of cyclone cylinder, ash collecting hopper, volute (or wind collecting cap) and other parts. According to the number of cylinders, it can be divided into five combinations: single cylinder, double cylinder, triple cylinder, quadruple cylinder and six cylinders.

Working Principle

CLT/A cyclone dust collector is a basic cyclone dust collector. Its top cover is made into a 15° spiral tangent shape. After the dust-laden gas enters the dust collector at a high flow rate (12~20m/s), it will flow downward along the inclined top cover without forming an upper ash ring. This can eliminate the small vortex airflow formed by the upward flow of the introduced airflow, reduce kinetic energy consumption, and improve dust removal efficiency. The dust-laden gas generates a large centrifugal force during the rotation process, which throws the dust particles to the wall of the device, thereby separating from the gas and falling into the ash hopper through the cone. The airflow is discharged outward through the volute (or air collecting cap).

Features

◎ Free combination, large air volume;

◎ Low cost, long service life;

◎ Simple structure, easy operation and maintenance;

◎ Pre-treatment for multi-stage dust removal.