USES

Central air conditioning is easy to use, but the astronomical price quotes force us to use Y5-47 boiler centrifugal induced draft fans in some occasions. Compared with the original Y547 fan, the Y5-47Ⅱ fan has undergone a series of improvements, so the noise is The number of machines has been significantly reduced, and the following seven machine numbers have been added to better meet the boiler matching requirements: N03.15C (E0.2th~o.5th).4D (t0.7th~ith).5D (West 2th). 6D (West t4th).7C (4th.6th).10D (Tt6th).11D (West E10Uh)

Y5-47Ⅱ boiler centrifugal induced draft fan is suitable for burning various coal qualities and is equipped with smoke and dust removal devices 0.2th~20th Industrial boilers with equivalent air inlet conditions and suitable performance can be used, but the maximum temperature shall not exceed 250℃.

FORM

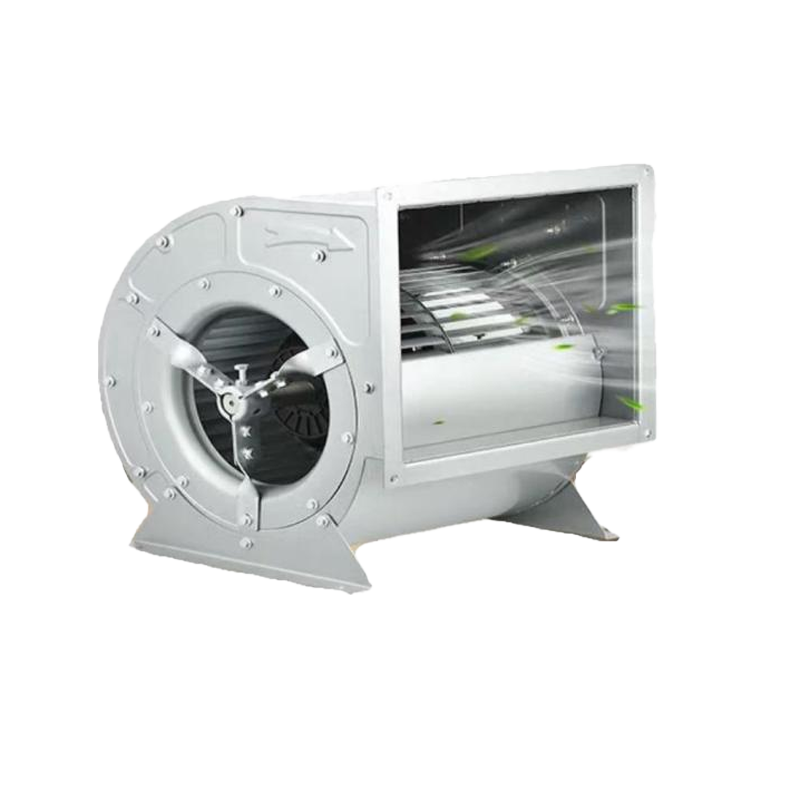

1. The induced draft fan is made of single suction, and the machine numbers are No. 3.15, 4, 5, 6, 7, 8, 9, 10, 11, 12, 12.4, a total of eleven.

2. The induced draft fan can be made into two types: left-handed and right-handed. Looking at the fan from one end of the transmission group, if the impeller is in the same direction, the fan can be made into three angles: 0°, 90°, and 180°.

4. The transmission mode of the fan is C type and D type, and the motor and the fan are connected by pulley drive and elastic coupling direct drive respectively.

5. If the above transmission mode, outlet angle and machine number cannot meet the production needs of your factory, I have the ability to design and modify according to the on-site conditions.

STRUCTURALFEATURES

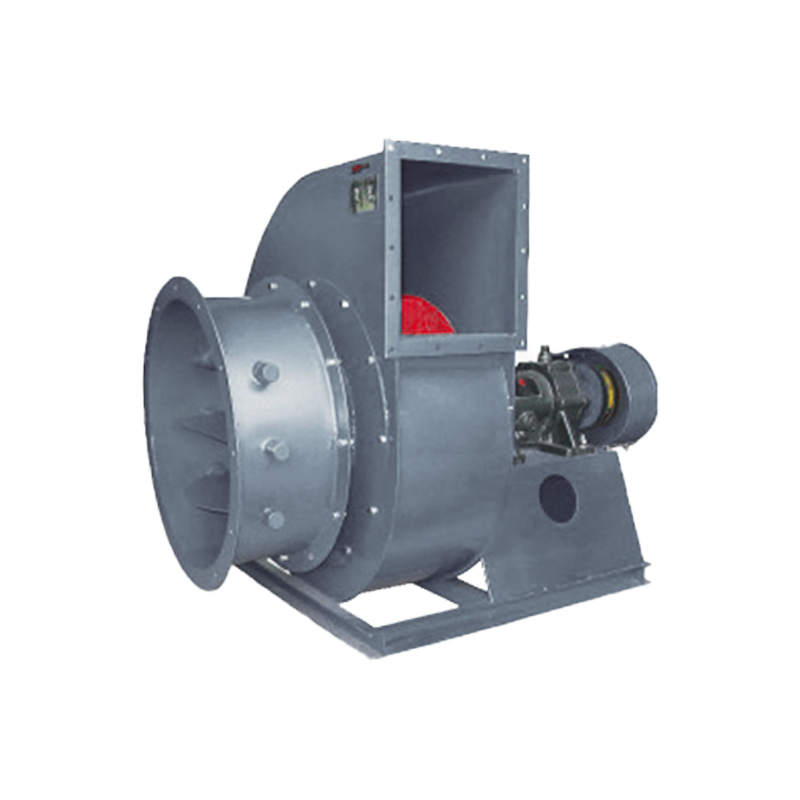

①Impeller – 12 pieces of 16Mn backward inclined flat blades are welded between the arc cone wheel cover and the flat wheel disc. After dynamic balancing and overspeed operation tests, the operation is stable and reliable. Its strength, wear resistance, service life and other key indicators are second to none among the famous fans.

②Casing – Ordinary steel plates are welded into a volute body. From N8 and above, “left” and “right” rotation are universal.

③Air inlet – The convergent air inlet is made into an integral structure and fixed to the side of the fan inlet with bolts.

④Adjustment door – Y5-47 series fans are equipped with adjustment doors to adjust the flow of the fan. Fans below N06 use 3 blades, a window-type structure, flexible closing and simple structure; fans above N7 use petal-shaped self-aligning adjustment doors, which have high adjustment efficiency and reliable structure. The adjustment door is axially installed in front of the air inlet, and the adjustment range is from 90 ( Fully closed) to 0′ (fully open), adjust the door handle position. From the air inlet direction, for right-hand rotating fans, the handle turns counterclockwise from fully closed to fully open, and for left-hand rotating fans, vice versa. To ensure the normal operation of the adjustment door, lubrication must be done well. Because the temperature of the induced draft fan is relatively high, high-temperature (260℃) slush grease is used for lubrication to ensure that it will not fail during high-temperature operation.

⑤ The main shaft of the transmission group is made of high-quality steel, with ball bearings (N03.15~7 low-noise bearings) and two parallel bearing seats, using No. 2 calcium-sodium based grease, the fan blades are self-cooled, and the structure is simple.

SPECIALPOINT

The Y5-47Ⅱ fan is an improved product based on the original Y5-47 fan. The fan has a full pressure internal efficiency of 85.6% at the best operating point, and a noise indication (A sound level) of 12.5dB.

There are many types of industrial boilers at present, and the quality of coal used varies greatly. The matching dust collectors and pipeline resistances are different, and the required induced draft fan air volume and air pressure vary greatly. To adapt to the above situation, the fan adopts two transmission modes, D type and C type (i.e. coupling and V-belt transmission). Among them, 0.7th~20th boilers are matched with D type transmission induced draft fans, and 0.2Uh~10th boilers are matched with C type transmission induced draft fans. For V-belt transmission, the user can change the main shaft speed according to the actual situation to obtain a more ideal air volume and air pressure.